Performances

Home page> Performances > Production

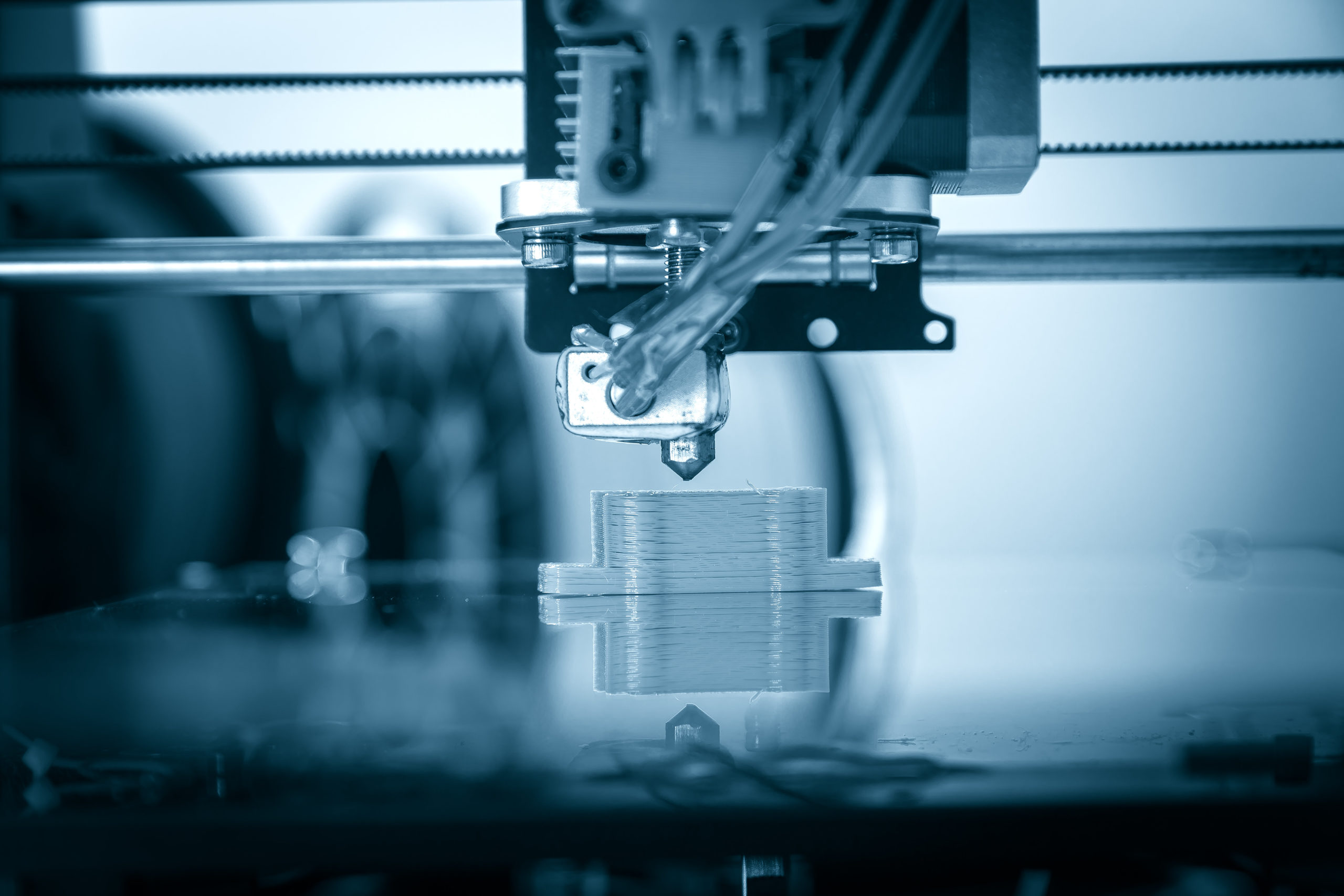

3D-Pressure

Printing

With HP Multi Jet Fusion, 3D printing has arrived in rapid manufacturing: consistent, stable and durable components, created with unprecedented efficiency and speed.

Small to medium-sized series printable.

Materials

Polyamide 12 (PA 12 ) is an 'all-rounder' engineering plastic that is versatile. The material convinces with its mechanical strength, chemical resistance and longevity.

TPU is a flexible plastic (Shore hardness approx. 90A) and sets new standards in additive manufacturing with its stability. The material is used for damping, handles, seals, grippers or heavily loaded housings and covers.

Your benefits with 3D printing

In addition to accurate results, additive manufacturing also offers advantages from the point of view of developers, designers and buyers. High costs for prototypes and long production times are a thing of the past.

The design possibilities are no longer limited and a fast production of a prototype enables faster detection of design errors, shortens the development phase and saves money. After that, scaling into series production is seamlessly possible.

Our innovative DeepDye Coloring (DDC) technology sets no limits to your color requirements. In addition to the more than 170 standard and RAL colors, which are ready for use at any time without additional development costs and waiting times, our Color Matching offer makes it possible to produce individual tones for you.

What makes us different?

At MMS Tec, we attach great importance to diversity in all directions. A professional printing process with high-quality materials, different colors and various surface finishes make it possible to meet your special wishes. No matter what it can be, MMS Tec makes it possible!

QUALITY

Our quality management is certified according to DIN 9001:2015 and guarantees you the desired safety and structure for your projects.

REGIONALITY

With our location in Pforzheim, we are your local partner in machining and accompany you individually in planning and production.

FLEXIBILITY

Machining depends on tailor-made dimensions and well thought-out concepts, which we make possible at any time with our flexibility.